The 8-Minute Rule for Plastic Bottle Suppliers

Table of ContentsPlastic Bottle Suppliers Can Be Fun For EveryonePlastic Bottle Suppliers - An OverviewThe smart Trick of Plastic Bottle Suppliers That Nobody is Talking AboutSome Ideas on Plastic Bottle Suppliers You Should KnowAll About Plastic Bottle SuppliersNot known Facts About Plastic Bottle Suppliers

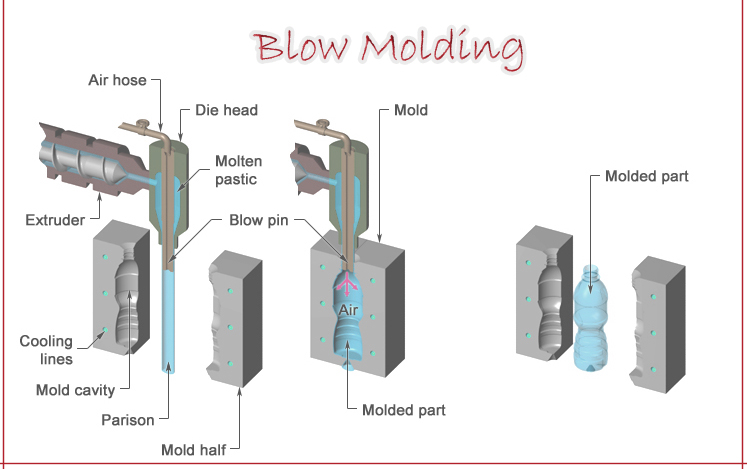

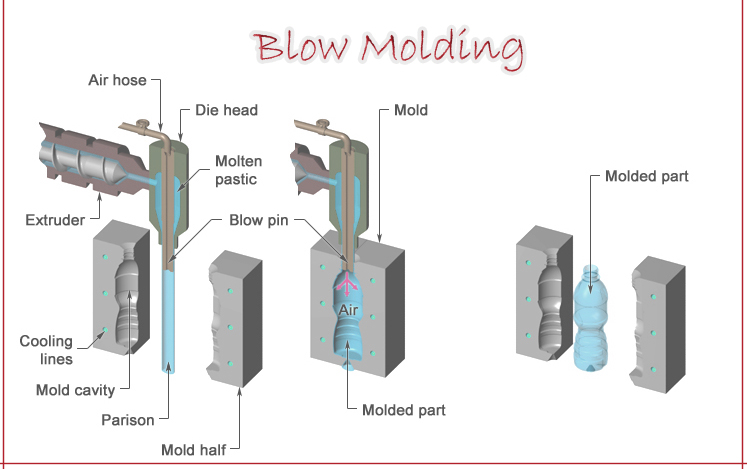

Created via a procedure known as, plastic containers are among the most commonly made use of drink containers in the contemporary globe. Using this procedure, plastic bottle makers are able to use a range of plastic products to produce bottles in a broad selection of shapes and also sizes. Generally, nonetheless, most plastic bottles are identified by thin wall surface construction, equally tiny sizes, lightweight and inexpensive.

To start this process, producers fill a receptacle with stock, which is a collection of little, raw polycarbonate pellets or fibers. From the receptacle, they direct the stock towards and guide it right into a conveyance channel in which resides a huge screw. As it transforms, this large screw pressures the supply and also presses it towards a mold cavity at the same time.

Once liquefied, the plastic is pushed into a mold cavity, where it takes on its form. Producers after that require pressed air right into the mold cavity, where the partly developed plastic product still rests. The objective of the pressed air is to make the plastic product hollow and also hold it against the body of the mold and mildew till it once more handles its shape.

A Biased View of Plastic Bottle Suppliers

From here, the product can be looked for blemishes and delivered, or sent out on for secondary handling. Sometimes, plastic container producers make use of the methods of shot impact molding (IBM) or injection stretch strike molding to make plastic bottles. (IBM) is performed in 3 major phases: shot, blowing and ejection. Throughout the initial stage, a liquified polymer is fed right into a hot runner manifold as well as infused via nozzles into a warmed cavity as well as onto a core pin.

Throughout the 2nd stage, this pin rotates its method to an impact molding station, where the mold is clamped around a core pole, inflated inside a preform and afterwards cooled down. Throughout the 3rd phase, once the plastic type has actually set, the finished product is moved right into the ejection placement as well as removed off the core pole.

Instead, it is just used to make small capacity bottles as well as jars. Likewise, manufacturers using this technique can not add handles or raise container barrier toughness. Next off, injection stretch strike molding is made use of to create rectangular, cylindrical and oval bottles. Shot stretch blow molding can be performed utilizing either approaches: single-stage or two-stage.

Things about Plastic Bottle Suppliers

In the 2nd technique, the preforms are created initially, utilizing the injection molding procedure, after that they are later on reheated stretched right into their designated sizes and shape. The last step is done using pressurized air and core poles, which help the preforms extend correctly - plastic bottle suppliers. To make their products, plastic container makers use a variety of different plastics, such as polyethylene, polyethylene terephthalate (PET DOG) and polypropylene.

Using recycled materials aids makers minimize their carbon footprint, as lots of plastics pose a hazard to the atmosphere otherwise recycled. Along these same lines, in enhancement to producing the containers themselves, numerous plastic container makers are likewise able to prepare utilized plastic bottles for use as recycled product in a spectacular number of applications, especially in the auto market.

Current price quotes claim that it takes why not find out more around 40 recycled plastic bottles to create the seat of an automobile. Recycling plastic bottles is a superb undertaking not just since it benefits the atmosphere, neither even if doing so aids producers comply with laws concerning recycling, yet because it is profitable; the need for recycled plastic items is high and also the cost to make them is low - plastic bottle suppliers.

How Plastic Bottle Suppliers can Save You Time, Stress, and Money.

Plastic Bottle Manufacturers R&D Molders, Inc. Plastic Bottle Manufacturers R&D Molders, Inc. Plastic Container Manufacturers Custom-Pak, Inc. Plastic Container Manufacturers R&D Molders, Inc. Plastic Container Manufacturers Custom-Pak, Inc. Plastic Container Manufacturers Custom-Pak, Inc.

The outside of the cap is generally textured rather than smooth to make it much easier to open and also normally click for more info have a lip at the end of the cap. It is not uncommon for there to be some sort of embossing to be present on top of the cap, generally providing directions as to just how to open the bottle (in the situation of medicinal containers) or in the form of a business logo design.

Plastic Bottle Suppliers - Questions

The threading inside the cover is defined in regards to tpi, or threads per inch, as well as the variety of strings used depends upon just how safe and secure the cap needs to be. In enhancement, there are conventional strings, skirt dimensions, and also cap dimensions that remain in use that make it simpler to match caps to bottles.

There are different kinds of heap, and also they can give different levels of security for the components of the container along with various kinds of tamper evident sealing. There might additionally be an outside meddle evident ring that breaks once the bottle cap has been Get More Info removed from the container.

The large majority of plastic bottle caps are made from recyclable plastics, with four of the most common being: PET (polyethylene terephthalate, # 1), which is solid and also lightweight and usually utilized for water container/ soft drink lids HDPE (high-density polyethylene, # 2), which is difficult, tight, but still lightweight LDPE (low-density polyethylene, # 4), which is flexible as well as has outstanding effect strength PP (polypropylene, # 5), which is hard, rugged, and also durable and also frequently made use of for bottle caps of all types Nonetheless, various other plastics may be utilized.

Getting The Plastic Bottle Suppliers To Work

The product selected for the bottle cap need to take into consideration qualities such as how lengthy it will be made use of (e. g., a container cap for a non reusable canteen will certainly not require to be as rugged as one for a prescription container intended to last for a month or longer), what kind of media is included (fluid, powder), and similar considerations.